Empower

Your Passion

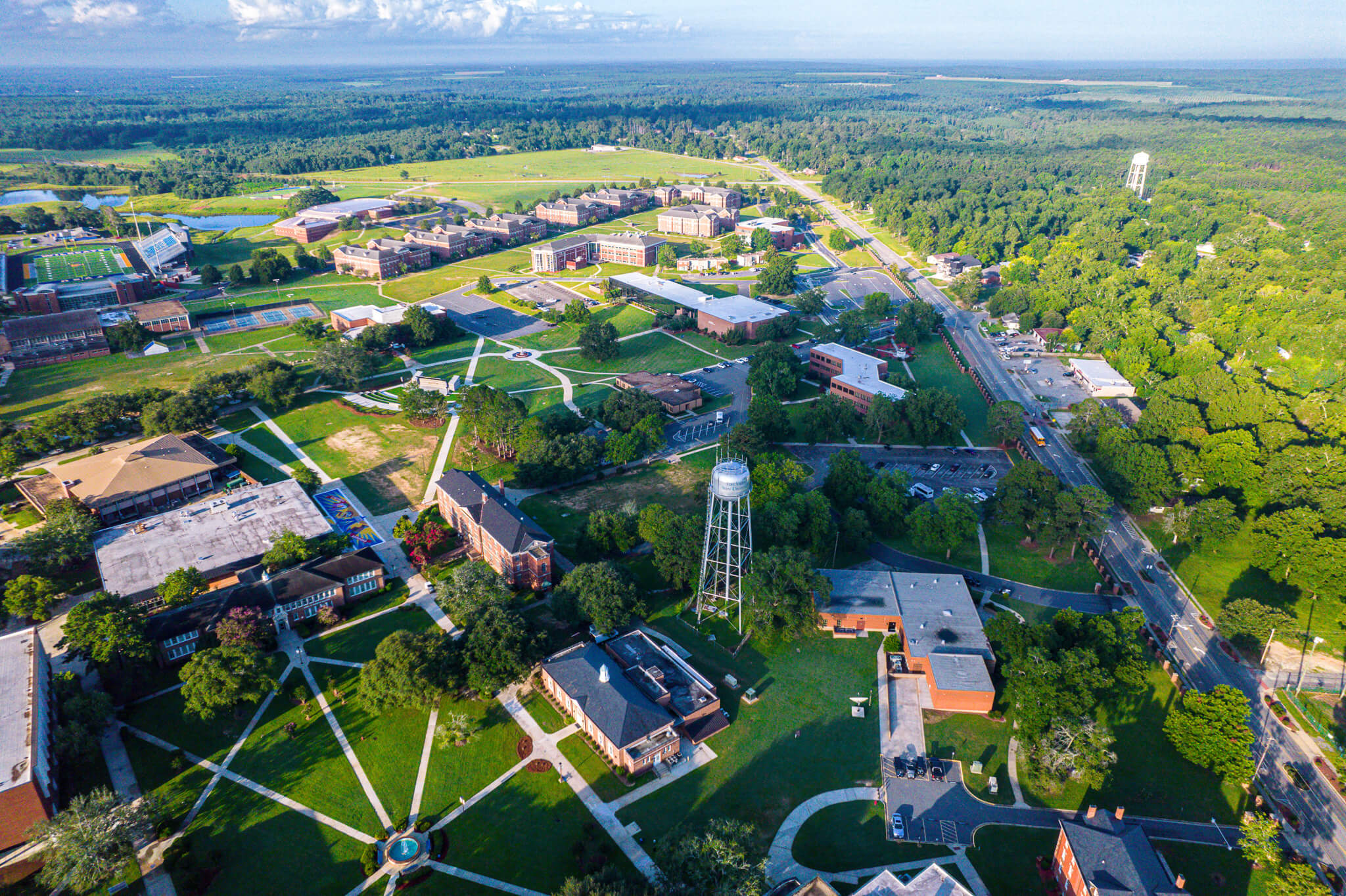

At Fort Valley State University, we empower students to push the boundaries of what is possible. With our dedicated faculty, state-of-the-art facilities, and innovated programs, we offer our students an unparalleled opportunity to explore their interests and prepare for a fulfilling career.

This Week

@ FVSU

There's always something happening in Wildcat Nation. View our campus calendar to stay up-to-date with the latest events on and off campus.

Empowering

Educational Dreams

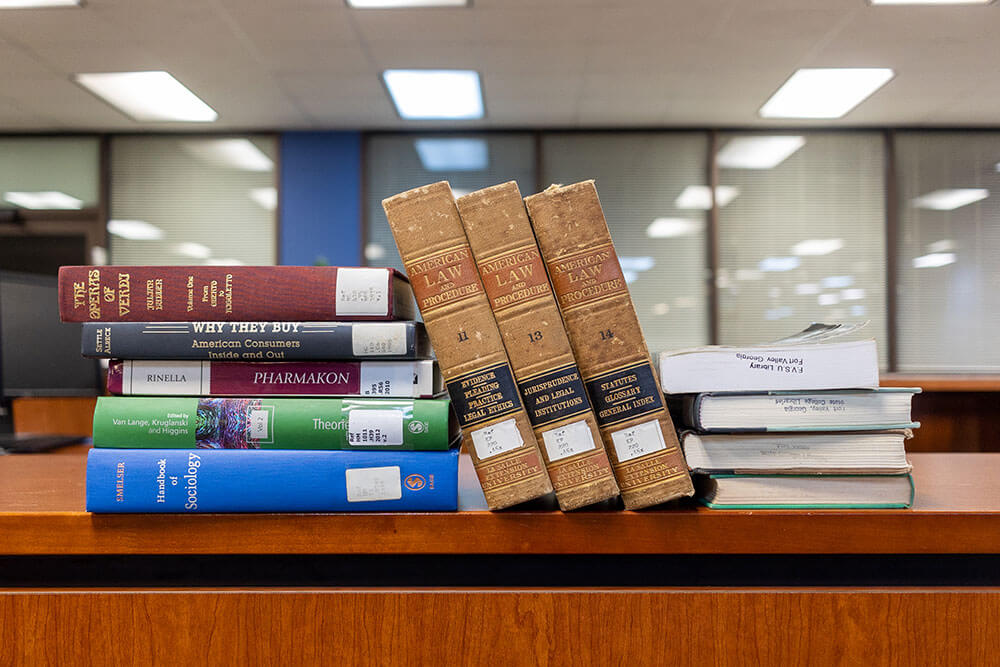

Financial Aid

Higher education is a profound financial commitment. Fort Valley State University is committed to making education accessible to students from all backgrounds.

Scholarships

To support our commitment to accessible and affordable education, Fort Valley State University offers a variety of competition and performance based scholarships.

Work Study

Fort Valley State University offers Federal Work-Study to help students cover a portion of their educational expenses while working on campus.

Excellence Empowers

Success

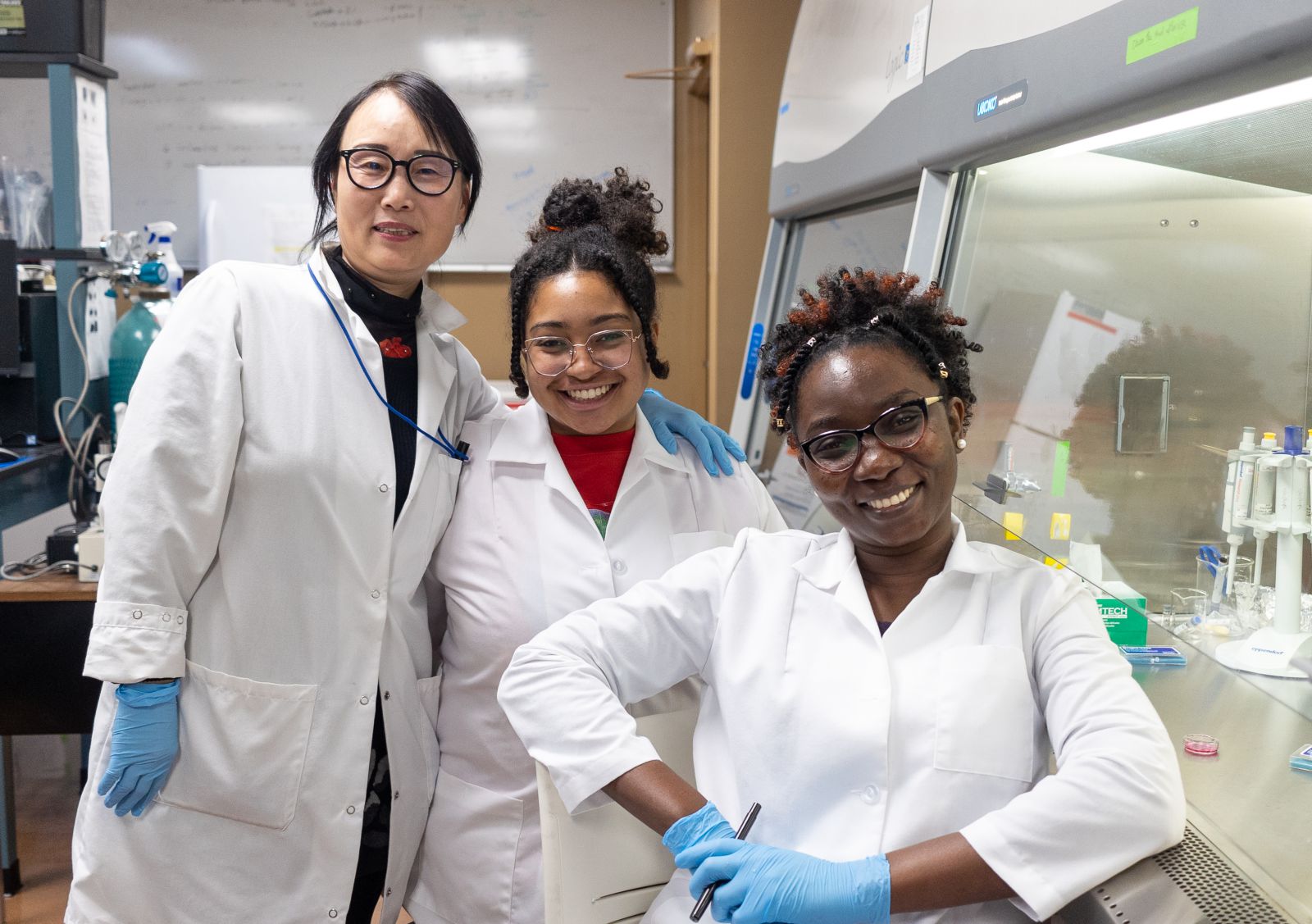

FVSU leverages its near 128-year tradition of excellence and uniqueness in academic and co-curricular programming to educate students and provide opportunities to engage directly in world-changing research with internationally recognized faculty members tackling complex global challenges.

A Message From

Paul Jones, Ph.D.

10th President

Founded in 1895, Fort Valley State University has a storied history, peopled by graduates that have gone on to impact the world of politics, industry, science and the arts. We provide our students an educational environment where opportunities in experiential learning and hands-on research abound. I invite you to join FVSU and EMPOWER the POSSIBLE.

.jpg)

Recent

News

Fort Valley State University faculty, staff, students and alumni are making headlines! Explore our pressroom and read the latest news from our University community.

.png)

Home

Three FVSU Students Awarded Prestigious Benjamin A. Gilman International Scholarship

Three FVSU students, Katelyn Davis, Ke'Irra Johnson, and Raven McRae, have been awarded the prestigious Benjamin A. Gilman International Scholarship to study abroad this summer.

1.png)

Home

Classroom Named in Honor of Ronald K. Abe

Classroom 112, in the Cozy L. Ellison Building, has been named after Ronald K. Abe, Ph.D.

.png)

Home

Fort Valley State University Celebrates Academic Excellence at 73rd Honors Convocation

Fort Valley State University marked a prestigious milestone as the 73rd Honors Convocation took place on March 28.

.png)

Home

FVSU Announces Spring 2024 Commencement Speaker

Daniel K. Wims, Ph.D., will be the featured speaker for Fort Valley State University’s Spring 2024 Commencement, scheduled for Saturday, May 11, 2024.